"Wrong Wheel Drive (41%)" (rduncan5678)

"Wrong Wheel Drive (41%)" (rduncan5678)

10/08/2015 at 13:49 ē Filed to: None

0

0

23

23

"Wrong Wheel Drive (41%)" (rduncan5678)

"Wrong Wheel Drive (41%)" (rduncan5678)

10/08/2015 at 13:49 ē Filed to: None |  0 0

|  23 23 |

I need to adjust my rear brakes via the adjuster screw since they are rubbing a bit on the rotor. I will probably end up needing to replace the caliper. However, the bolt blocking the adjustment screw is stripped to all hell. I tried getting it off but to no luck. What are your favorite methods for removing a destroyed bolt? The head is nearly completely rounded at this point...

Urambo Tauro

> Wrong Wheel Drive (41%)

Urambo Tauro

> Wrong Wheel Drive (41%)

10/08/2015 at 13:56 |

|

50:50 ATF/acetone home-made penetrant (preferably soaking overnight), sharply tap the bolt with a punch to ďshockĒ the threads, heat the area around the bolt (not the bolt itself), six-point socket (not 12), if already rounded use a bolt extractor or locking pliers (Vise-Grips).

SnapUndersteer, Italian Spiderman

> Wrong Wheel Drive (41%)

SnapUndersteer, Italian Spiderman

> Wrong Wheel Drive (41%)

10/08/2015 at 14:06 |

|

New car

TTercel

> Urambo Tauro

TTercel

> Urambo Tauro

10/08/2015 at 14:10 |

|

This guy knows whatís up!

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Urambo Tauro

Jake Huitt - Two Alfas And A Nissan, Not A Single Running Car

> Urambo Tauro

10/08/2015 at 14:11 |

|

And a sawzall as a last resort...

(1993 dodge dakota shocks may be a bit rusty. Ask me how I know....)

Kofi

> Wrong Wheel Drive (41%)

Kofi

> Wrong Wheel Drive (41%)

10/08/2015 at 14:27 |

|

New caliper, the amount of work to get a frozen bolt or bleeder screw in a caliper is not worth the 50-100 of a reman caliper

deekster_caddy

> Wrong Wheel Drive (41%)

deekster_caddy

> Wrong Wheel Drive (41%)

10/08/2015 at 14:45 |

|

Vice grips and heat. Sometimes if you are lucky you can get a bolt extractor to grab it. If none of that works cut or drill the head off. I prefer drilling, hopefully you have some space to get at/around the thing. When they are in tight quarters it really sucks.

Can you take the caliper bracket off with the caliper still on and work on it on a bench? (will need to disconnect the brake hose for this, but itís a last resort anyway)

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> Wrong Wheel Drive (41%)

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> Wrong Wheel Drive (41%)

10/08/2015 at 14:50 |

|

I used a Speedout once, it works fine. Just don't plan on using it more than once, I had one shear its own head right off on a bolt the second time I used it.

Wrong Wheel Drive (41%)

> deekster_caddy

Wrong Wheel Drive (41%)

> deekster_caddy

10/08/2015 at 15:10 |

|

Access is certainly annoying, I had not thought about removing the whole caliper assembly since I didnít want to have to bleed the brakes. But yeah that would definitely make my life a ton easier. The only problem is that I cannot safely release the caliper without using the adjustment screw behind that bolt. So getting the caliper off would be problematic.

Wrong Wheel Drive (41%)

> That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

Wrong Wheel Drive (41%)

> That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

10/08/2015 at 15:10 |

|

What is a speedout?

Wrong Wheel Drive (41%)

> SnapUndersteer, Italian Spiderman

Wrong Wheel Drive (41%)

> SnapUndersteer, Italian Spiderman

10/08/2015 at 15:10 |

|

lol great suggestion

Wrong Wheel Drive (41%)

> Urambo Tauro

Wrong Wheel Drive (41%)

> Urambo Tauro

10/08/2015 at 15:14 |

|

ATF, would be nice if I had anything automatic. Would just some off the shelf penetrant do the same job? It is definitely already rounded and I was having no joy with vice grips. But I think a better fitting set of vice grips and a good penetrant should be able to get that thing off. I had tried using a bolt extractor too but the metal in the bolt was kinda too soft and I didnít really know what I was doing anyways. I may be able to drill in further in the bolt to get it to work. Access is rather tight for drilling, the control arm is very much in the way.

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> Wrong Wheel Drive (41%)

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> Wrong Wheel Drive (41%)

10/08/2015 at 15:22 |

|

Basically a two sided bit. You use one end to bore into the head of the fastener, then you flip it over and the other end is a reverse thread that bites into the hole you just drilled and backs the fastener out.

Urambo Tauro

> Wrong Wheel Drive (41%)

Urambo Tauro

> Wrong Wheel Drive (41%)

10/08/2015 at 15:28 |

|

Curved-jaw Vise-Grips would probably give you the best grip.

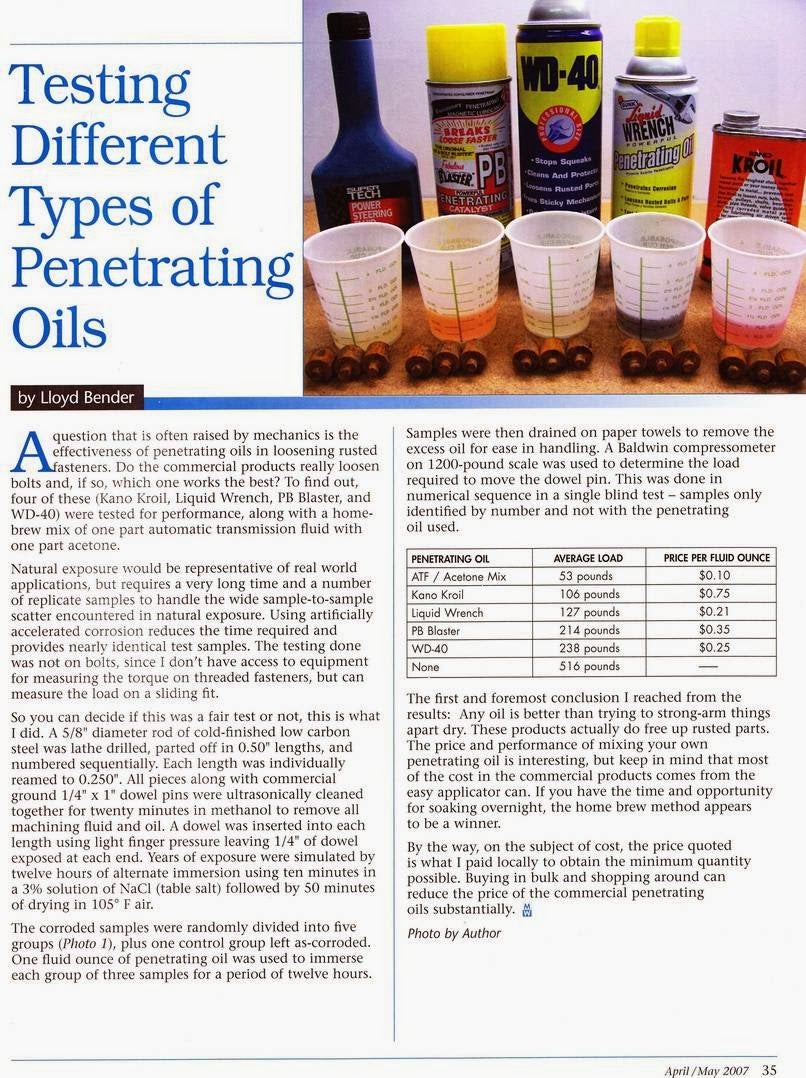

Itís best to use a good penetrant, but even WD-40 is better than nothing. I switched to the home-made stuff after reading this article ( Machinistís Workshop, April/May 2007 ):

Wrong Wheel Drive (41%)

> That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

Wrong Wheel Drive (41%)

> That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

10/08/2015 at 15:35 |

|

Ahh okay so any normal bolt-extraction-kit would be that type of thing. Sounds useful to have it dual sided though for sure! I had tried the extraction kit I had laying around but none were really the right size and I was having trouble with the softness of the bolt and access to the bolt head anyways.

Master Cylinder

> Wrong Wheel Drive (41%)

Master Cylinder

> Wrong Wheel Drive (41%)

10/08/2015 at 15:44 |

|

Weld a nut onto the ruined bolt. The heat of welding plus having a solid surface to wrench on again works wonders. As long as you donít accidentally weld the bolt in place, 100% of the time, it works every time.

Wrong Wheel Drive (41%)

> Master Cylinder

Wrong Wheel Drive (41%)

> Master Cylinder

10/08/2015 at 15:47 |

|

haha first thing I thought of when I saw ďweldingĒ was the bolt getting welded to the surface and making matters even worse. Now I just need someone with welding skills and equipment! Might try some less invasive methods first though. I didnít have any penetrator, only brake cleaner, so I will have to get some PB blaster or something.

Master Cylinder

> Wrong Wheel Drive (41%)

Master Cylinder

> Wrong Wheel Drive (41%)

10/08/2015 at 15:50 |

|

Yeah, itís tricky when itís a steel bolt in a steel or iron hole, if youíre not careful with the weld you can turn an annoyance into a disaster.

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> Wrong Wheel Drive (41%)

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> Wrong Wheel Drive (41%)

10/08/2015 at 16:40 |

|

Yeah, exactly. Speedout is the actual product name. Theyíre handy for small stuff, a set of 4 sizes goes for like $15 at Sears. Itís better than nothing, haha.

BaconSandwich is tasty.

> Urambo Tauro

BaconSandwich is tasty.

> Urambo Tauro

10/08/2015 at 20:27 |

|

I really wish someone would do some more testing on this. Thatís some very interesting results!

Urambo Tauro

> BaconSandwich is tasty.

Urambo Tauro

> BaconSandwich is tasty.

10/08/2015 at 20:31 |

|

The homebrew kicks ass, and Iím pretty pleased with the testing method.

But, the article is over 8 years old. Some companies do change their formulas over time. I wonder if something even better has been developed...

BaconSandwich is tasty.

> Urambo Tauro

BaconSandwich is tasty.

> Urambo Tauro

10/08/2015 at 21:02 |

|

Now that just raised an interesting kind-of related thought: I think it would be quite interesting to set up a Jalop-wiki. Itíd be the perfect place for posting results from articles like that.

brianbrannon

> Wrong Wheel Drive (41%)

brianbrannon

> Wrong Wheel Drive (41%)

10/09/2015 at 21:40 |

|

I think your diagnosis is wrong. If the caliper is dragging the piston is sticking or the slides are seized or the pads are rusted in place. The service screw is only used when replacing the pads. That cover screw is sometimes left handed thread BTW

Wrong Wheel Drive (41%)

> brianbrannon

Wrong Wheel Drive (41%)

> brianbrannon

10/13/2015 at 11:31 |

|

If the piston is sticking or the slides are seized, then the caliper would need to be replaced. Anything I have read about removing the caliper states that the service screw should be loosened first before trying to remove the caliper. This is because it will be holding the pads tightly to the rotor and removal would damage the pads and/or rotor if you do not loosen it. In any case, I need to remove that cover screw to continue my investigation. It appears to not be rubbing anymore with just the e-brake disconnected so I may just need to adjust the slack. Anyways, I also confirmed it is not left handed thread since the drivers side came off just fine with counterclockwise rotation (in relation to the hole).